Sustainable Practices in Electronics Manufacturing

The electronics industry, a cornerstone of modern society, faces increasing pressure to adopt more sustainable practices. From the initial design phase to manufacturing, distribution, and end-of-life management, every stage of an electronic device's lifecycle carries an environmental footprint. Addressing these challenges requires a comprehensive approach, focusing on reducing resource consumption, minimizing waste, and promoting circular economy principles. This shift is crucial for mitigating environmental impact and ensuring the long-term viability of technological advancement.

Sustainable Design and Material Selection for Electronics

Sustainable practices in electronics manufacturing begin with thoughtful design and material choices. Creating gadgets and devices with longevity and repairability in mind is fundamental. This involves selecting materials that are less harmful to the environment, such as recycled plastics, bio-based polymers, or sustainably sourced metals, rather than relying solely on virgin resources. Modular designs, for instance, allow for easier replacement of components like displays or circuits, extending the overall lifespan of hardware and reducing the need for complete device replacement.

Furthermore, the design process can incorporate features that facilitate future recycling. This includes using fewer different types of materials, avoiding permanent bonding methods, and clearly labeling components for easier sorting during end-of-life processing. Such considerations are vital for reducing electronic waste and conserving valuable resources.

Energy Efficiency in Manufacturing Processes

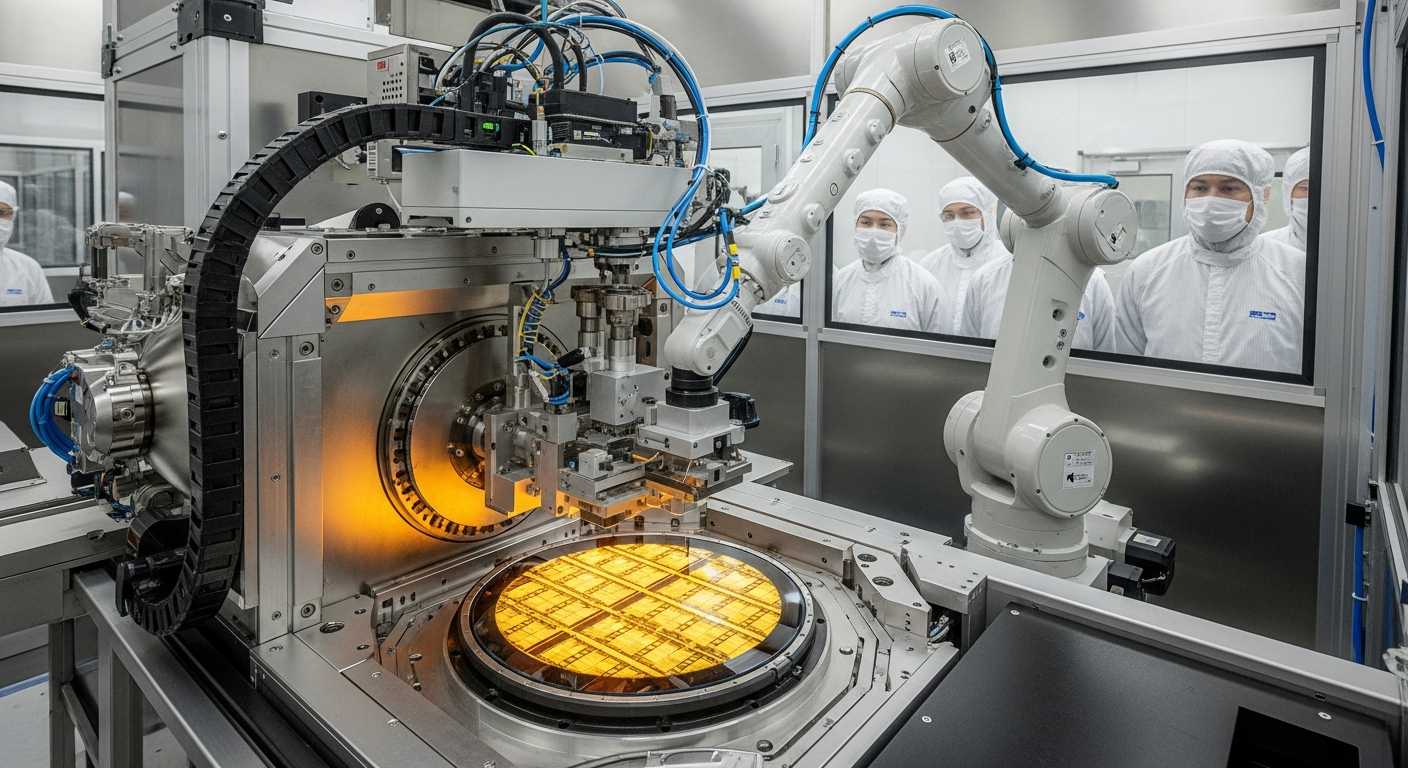

Manufacturing processors and microchips is an energy-intensive process, demanding significant amounts of electricity and water. Implementing power efficiency measures in production facilities is therefore a critical aspect of sustainable electronics manufacturing. This can involve optimizing machinery, utilizing renewable energy sources, and improving facility insulation to reduce heating and cooling demands.

Advanced automation and robotics can also play a role in enhancing efficiency. By streamlining production lines and minimizing human error, automated systems can reduce material waste and optimize energy use. Continuous monitoring and data analysis of energy consumption help identify areas for further improvement, leading to a more sustainable and cost-effective manufacturing operation.

Enhancing Product Lifespan and Resource Recovery

Extending the lifespan of electronic products, from personal devices to large-scale storage systems, is a key component of sustainability. This involves designing products that are durable, upgradeable, and repairable. When products do reach their end-of-life, effective resource recovery mechanisms are essential. Establishing robust collection and recycling programs ensures that valuable materials are extracted and reintroduced into the manufacturing cycle, rather than ending up in landfills.

Responsible management of data and secure deletion practices are also important aspects of the digital product lifecycle, especially when devices are refurbished or recycled. Promoting a circular economy approach for connectivity hardware means that components are not just disposed of, but are seen as resources for future products, minimizing the environmental impact of new production.

Innovation Driving Future Sustainable Electronics

Innovation is at the forefront of driving sustainability in the electronics sector. Breakthroughs in software optimization can reduce the energy consumption of devices, making them more efficient even with existing hardware. Developments in low-power computing and advanced sensors enable devices to perform complex tasks with minimal energy, extending battery life and reducing the frequency of charging.

Research into new materials, such as self-healing polymers or more energy-efficient displays, continues to push the boundaries of what is possible. Furthermore, the development of smarter networks and improved data center efficiency contributes to a greener digital infrastructure. These advancements collectively pave the way for a future where electronic products are not only powerful and connected but also environmentally responsible throughout their entire lifecycle.

The pursuit of sustainability in electronics manufacturing is an ongoing journey that requires continuous effort and collaboration across the industry. By integrating eco-conscious design, energy-efficient production, and robust recycling initiatives, the sector can significantly reduce its environmental footprint. Embracing innovation and adopting circular economy principles will be crucial for creating a more sustainable future for electronic devices and the planet.