Smart Asset Optimization Through Condition-Based Maintenance

Industrial equipment operating beyond optimal conditions costs global businesses billions annually. Condition-Based Maintenance (CBM) represents a strategic shift from traditional maintenance approaches, enabling organizations to detect equipment issues before catastrophic failure occurs. By continuously monitoring machine health parameters through advanced sensors and analytics, companies are transitioning from reactive emergency repairs to proactive maintenance scheduling. This methodology not only extends equipment lifespan but dramatically improves operational reliability while reducing overall maintenance expenditures. The integration of CBM into asset management strategies is becoming increasingly essential for maintaining competitive advantage in manufacturing, utilities, and process industries.

Understanding the Evolution of Maintenance Strategies

The industrial maintenance landscape has undergone significant transformation over the past century. Early 20th century factories operated under a “run-to-failure” model, where equipment remained in service until breakdown—a costly approach that resulted in unpredictable downtime and production losses. The 1950s introduced preventive maintenance schedules based on time intervals rather than actual equipment condition. While this represented improvement, it often resulted in unnecessary maintenance and replacement of components that still had useful life remaining.

By the 1980s, organizations began implementing reliability-centered maintenance (RCM), focusing resources on critical equipment. This period also saw the first iterations of condition monitoring, though limited by technological capabilities of the era. Modern CBM emerged in the early 2000s, enabled by advances in sensor technology, wireless connectivity, and data analytics. Today’s sophisticated CBM systems leverage these technologies to provide real-time equipment health assessments, transitioning maintenance from art to science and allowing organizations to maintain production assets based on actual performance data rather than assumptions or schedules.

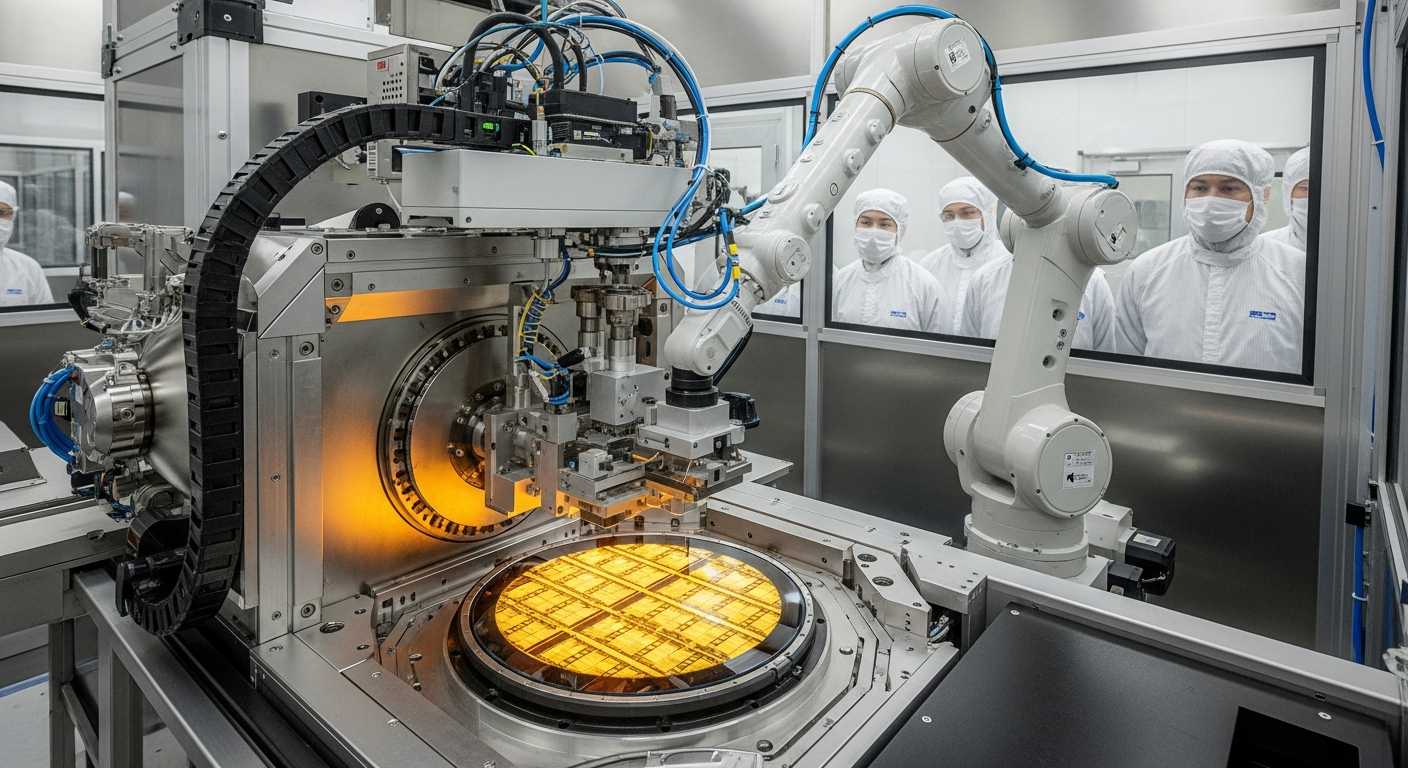

The Technical Foundations of Condition-Based Maintenance

At its core, CBM relies on capturing and interpreting equipment performance data through various monitoring techniques. Vibration analysis detects abnormal movement patterns that may indicate bearing wear, misalignment, or impending mechanical failure. Oil analysis examines lubricant samples for contaminants, metal particles, and viscosity changes, providing insights into internal component conditions. Thermographic imaging identifies overheating components by measuring infrared radiation patterns, while ultrasonic inspection detects high-frequency sounds associated with pressure leaks, electrical discharges, or mechanical friction.

Modern CBM systems integrate these monitoring methods with machine learning algorithms that establish baseline equipment behavior and detect subtle deviations from normal operating parameters. These systems identify not only that something is wrong but also diagnose the specific issue and its severity. Continuous parameter tracking allows maintenance teams to observe deterioration trends over time, enabling precise prediction of when components will reach critical thresholds. The resulting data-driven maintenance decisions optimize resource allocation and minimize unnecessary equipment interventions.

Financial Implications and ROI Considerations

The business case for CBM implementation revolves around four key financial drivers: reduced downtime costs, extended equipment lifecycle, optimized labor utilization, and inventory management efficiencies. Unplanned downtime typically costs manufacturers between $30,000 and $50,000 per hour, with some high-volume production environments reporting losses exceeding $1 million hourly. By preventing unexpected failures, CBM directly impacts the bottom line by maintaining production continuity.

Component replacement based on actual condition rather than fixed intervals extends useful equipment life by 20-40% according to industry studies. This postpones capital expenditures on replacement equipment while increasing return on existing assets. From a labor perspective, CBM allows maintenance teams to work more efficiently by eliminating emergency repairs and focusing on scheduled interventions. The inventory side benefits from reduced spare parts holdings, as maintenance can be planned with sufficient lead time to procure components just-in-time rather than maintaining extensive on-site inventories.

Case studies demonstrate impressive ROI figures, with CBM implementations typically delivering 3:1 to 10:1 returns depending on industry and application. A North American paper mill documented 91% reduction in unplanned downtime and $1.2 million annual savings after implementing vibration monitoring on critical rotating equipment. Similarly, a European automotive manufacturer reported 37% reduction in maintenance costs while increasing equipment availability by 12% through comprehensive CBM implementation.

Implementation Strategy and Change Management

Successful CBM adoption requires a structured approach beginning with critical asset identification. Organizations should prioritize equipment based on failure impact, replacement cost, and operational significance. For selected assets, appropriate monitoring technologies must be determined based on failure modes and criticality. This may involve retrofitting existing equipment with sensors or specifying monitoring capabilities for new purchases.

The human factor remains crucial despite technological advancements. Effective CBM implementation includes comprehensive training programs that develop both technical skills for data interpretation and change management capabilities to shift organizational culture. Maintenance teams must transition from “wrench-turners” to “data analysts” who understand how to translate sensor readings into maintenance decisions. Equally important is leadership commitment, as CBM represents a philosophical shift requiring sustained investment in technology, training, and process development.

A phased implementation approach typically yields the best results, beginning with pilot programs on high-value equipment to demonstrate concept viability. Initial successes build organizational momentum and provide learning opportunities before broader deployment. Regular program assessment ensures alignment with business objectives and identifies opportunities for continuous improvement as technologies evolve.

Future Trends in Equipment Health Monitoring

The CBM landscape continues evolving with emerging technologies expanding monitoring capabilities and improving decision support. Advanced analytics incorporating machine learning algorithms now detect subtle pattern changes invisible to human analysts, identifying potential failures weeks or months before traditional methods. These systems become increasingly accurate over time as they process more equipment performance data.

Remote monitoring capabilities allow experts to analyze equipment regardless of geographical location, supporting centralized excellence centers that serve multiple facilities. Mobile technology delivers diagnostic information directly to technicians’ devices, providing guidance during inspection and repair activities. Meanwhile, digital twin modeling creates virtual replicas of physical assets that simulate different operating conditions, enabling “what-if” scenarios to optimize maintenance timing.

The integration of CBM with broader operational technology systems represents perhaps the most significant development. Rather than functioning as standalone systems, modern CBM platforms connect with production scheduling, enterprise resource planning, and supply chain management systems. This integration enables truly optimized decision-making that considers not only equipment condition but also production demands, resource availability, and business priorities.

Strategic Implementation Guidelines

-

Begin with a comprehensive equipment criticality assessment to identify high-value targets for monitoring

-

Select monitoring technologies appropriate to specific failure modes rather than adopting a one-size-fits-all approach

-

Establish clear baseline performance metrics before implementation to enable accurate ROI measurement

-

Invest in data management infrastructure capable of handling the volume of information generated by monitoring systems

-

Develop clear decision protocols that translate condition data into maintenance actions with defined thresholds

-

Create integration pathways between maintenance systems and operational technologies to maximize value

-

Establish ongoing training programs that continuously develop technical capabilities as technologies evolve

-

Implement regular program reviews comparing actual outcomes against projected benefits

As industrial operations face increasing pressure to maximize efficiency and equipment utilization, condition-based maintenance offers a strategic approach to asset management that aligns with these objectives. By detecting potential failures before they impact operations, organizations can systematically reduce costs while improving reliability and production continuity. While implementation requires careful planning and organizational commitment, the financial and operational benefits make CBM an essential component of modern industrial strategy. As monitoring technologies continue advancing, the gap between organizations leveraging data-driven maintenance approaches and those relying on traditional methods will likely determine competitive positioning in increasingly challenging market environments.