Enhancing Operational Efficiency in Modern Enterprises

In today's dynamic global marketplace, modern enterprises face continuous pressure to optimize their operations, reduce costs, and accelerate value delivery. Achieving superior operational efficiency is not merely an advantage but a fundamental necessity for sustained growth and competitiveness. This article delves into various strategies and technological advancements that businesses can leverage to streamline processes, improve resource utilization, and foster a more agile and responsive operational framework across their entire ecosystem, from manufacturing floors to complex supply chains.

Modern enterprises are constantly seeking ways to refine their internal workings and external interactions to remain competitive. Operational efficiency, at its core, involves performing tasks and processes in the most effective and resource-efficient manner possible, translating directly into improved productivity, reduced waste, and enhanced profitability. This pursuit requires a holistic approach, integrating various facets of an organization’s functions.

Optimizing Manufacturing and Production Processes

Manufacturing and production lie at the heart of many enterprises. Enhancing efficiency in these areas often involves adopting lean manufacturing principles, which focus on eliminating waste in all its forms—overproduction, waiting, unnecessary transport, over-processing, excess inventory, unnecessary motion, and defects. Implementing advanced planning and scheduling systems can help synchronize production activities, optimize resource allocation, and reduce bottlenecks. Furthermore, quality management systems play a crucial role in minimizing rework and ensuring consistent output, contributing significantly to overall production efficiency.

Streamlining Logistics and Supply Chain Management

Effective logistics and supply chain management are critical for ensuring that raw materials flow smoothly into production and finished goods reach customers efficiently. Modern strategies emphasize end-to-end visibility across the supply chain, allowing enterprises to track goods, anticipate disruptions, and respond proactively. Technologies such as warehouse management systems (WMS) and transportation management systems (TMS) optimize storage, picking, packing, and shipping processes. Collaboration with suppliers and distributors, coupled with data-driven forecasting, helps reduce inventory holding costs and improve delivery times, enhancing the entire value chain.

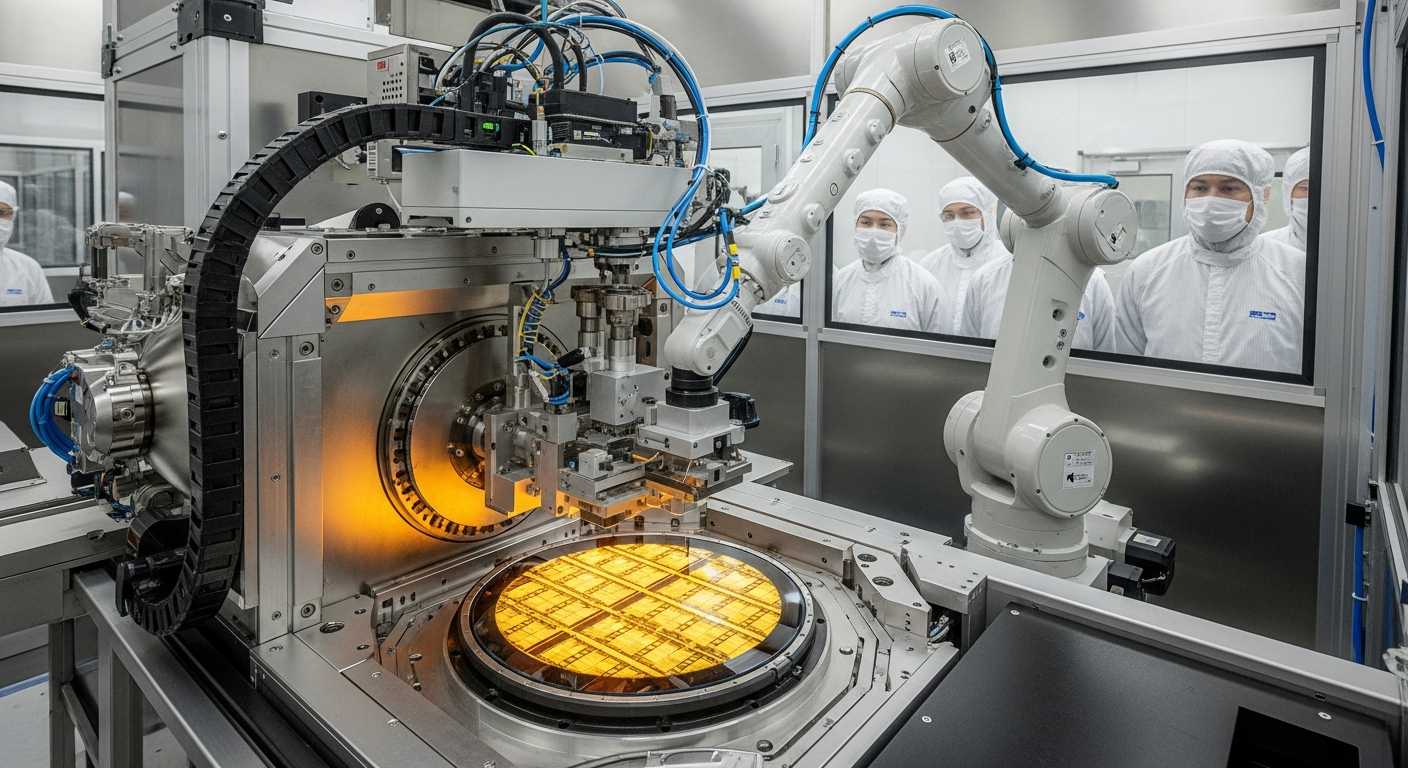

The Role of Automation in Enterprise Operations

Automation is a powerful driver of operational efficiency across various enterprise functions. In manufacturing, robotic process automation (RPA) and industrial robots can handle repetitive, high-volume tasks with greater speed and accuracy than human workers, leading to increased throughput and reduced errors. Beyond the factory floor, automation extends to administrative tasks, customer service, and data processing, freeing human employees to focus on more complex, strategic activities. This not only boosts productivity but also improves consistency and compliance within operations.

Strategic Approaches to Operations Management

Effective operations management involves the strategic planning, execution, and control of all activities involved in the production of goods or services. This includes capacity planning, inventory management, process design, and quality control. Strategic operations management aligns operational goals with overall business objectives, ensuring that every process contributes to the enterprise’s mission. Continuous improvement methodologies, such as Six Sigma and Kaizen, foster a culture of ongoing optimization, encouraging teams to identify and implement incremental improvements that collectively lead to significant gains in efficiency over time.

Leveraging Technology for Industry-Wide Efficiency

The broader industry landscape benefits immensely from technological advancements that drive efficiency. Beyond automation, technologies like the Internet of Things (IoT) provide real-time data from machinery and assets, enabling predictive maintenance and optimizing equipment performance. Artificial intelligence (AI) and machine learning (ML) can analyze vast datasets to uncover patterns, predict demand, and optimize complex operational decisions, from route planning in logistics to resource allocation in production. Cloud computing offers scalable infrastructure, facilitating collaboration and data access across geographically dispersed operations, further enhancing overall industry efficiency.

Operational efficiency is a continuous journey rather than a destination for modern enterprises. By strategically implementing advanced technologies, embracing lean principles, and fostering a culture of continuous improvement, businesses can not only meet current market demands but also build a resilient and agile operational framework capable of adapting to future challenges and opportunities. The integration of manufacturing, logistics, supply chain, and overall operations management under a unified vision is paramount for achieving sustained success in today’s competitive environment.